Service Bar Rail Wait Station Area Divider for Bars, Restaurants, Pubs, and More

$300.00

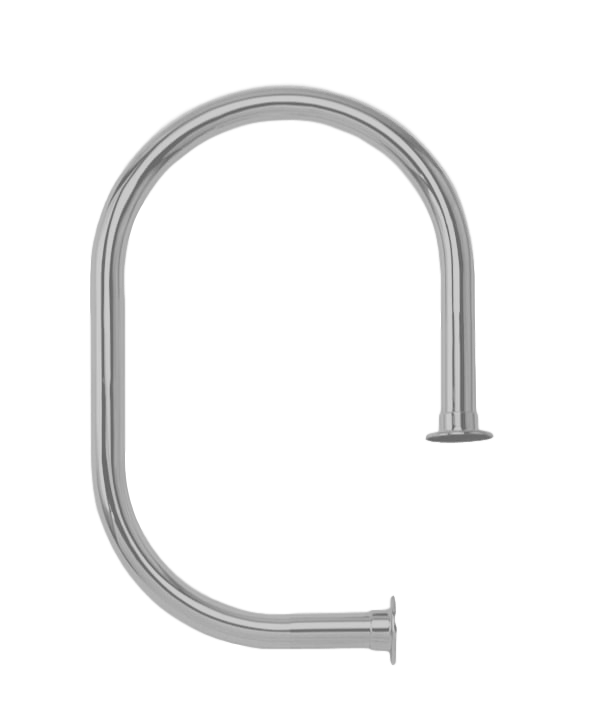

- Polished Stainless Steel

- BRUSHED BRASS - UNCOATED - PER RAIL

- Antique Brass powder coat finish

- Brushed Brass - Uncoated - Buy a pair and save

- Brushed Brass with matte clear coat - please call

- Brushed Stainless Steel

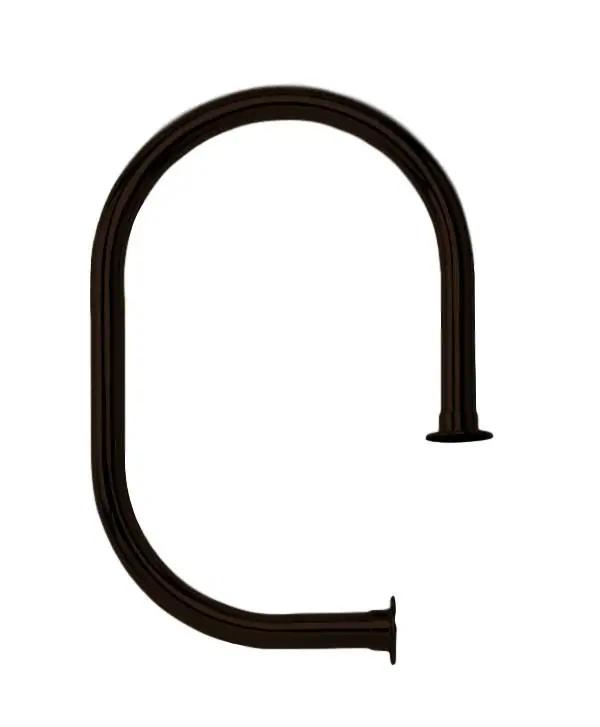

- Oil-Rubbed Bronze Powder Coated Finish - Special Finish - Please Call

- Matte Black Powder Coated Finish - Special Finish - Please Call

- Polished Brass

Service Bar Rail Wait Station Area Divider for Bars, Restaurants, Pubs, and More

Product Description

Streamline your bar service with our industrial-grade service bar rail divider. Engineered for high-traffic bars, restaurants, hotels, pubs, and nightclubs. Features antimicrobial brass construction, quick installation, and premium finishes.

Key Features:

- Quick & Easy Installation – Flexible design adapts to various bar layouts for a hassle-free setup.

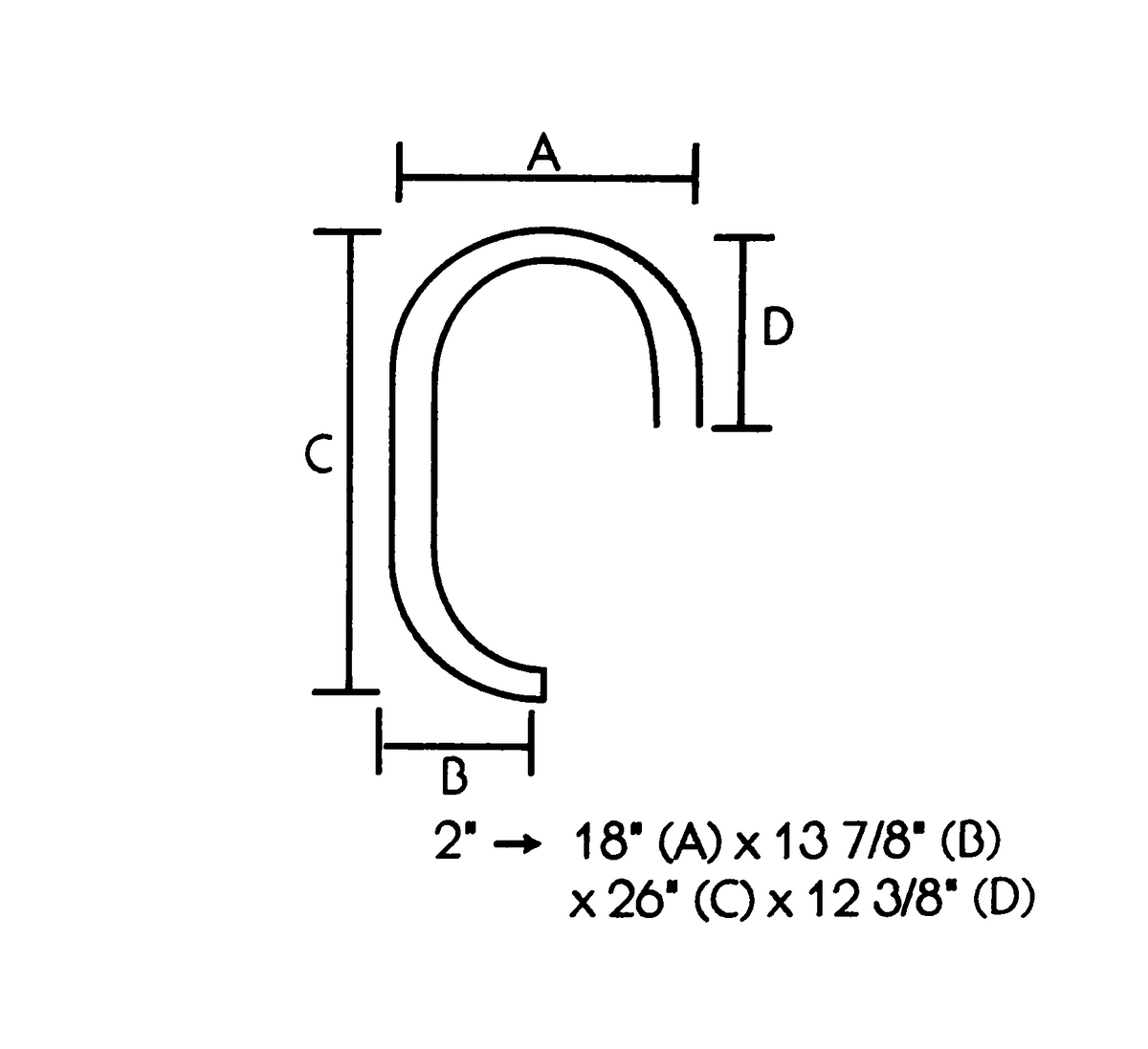

- Heavy-Duty 2" Tubing Construction – Sturdy, long-lasting build that securely attaches to both the top and face of your bar.

- Flanges Included – At No Extra Cost – Choose between Wall or Narrow Flanges for seamless installation.

- Naturally Antimicrobial Brass – Helps maintain a cleaner, more hygienic environment.

- Premium Finishes to Match Any Space – Available in Polished Brass, Polished

- Stainless Steel, Brushed Stainless Steel, Matte Black, and Oil-Rubbed Bronze. Custom powder-coated finishes are also available upon request.

🚨 High Demand Notice: Polished brass is temporarily unavailable. Explore our other premium finishes while supplies last!

Why Choose Our Service Bar Rail?

- Designed for Commercial Use – Engineered for the demands of busy hospitality venues.

- Stylish & Functional – Optimizes workflow while keeping your space professional and polished.

- Made from High-Quality Brass or Stainless Steel – Withstands heavy use in high-traffic environments.

Customization Options:

- Pre-Mounted Flanges Available – Request pre-mounted flanges for faster installation.

- Custom Finish Inquiries – Contact us for details on lead times and pricing for specialty finishes.

- Brass Product Details – Solid brass with a mirror-polished finish. Optional glossy, brushed, or matte clear powder coat finishes available (additional charges apply).

📦 Fast Shipping – Order Now to Upgrade Your Bar Setup!

Shipping

DELIVERY

In-stock items typically leave our Ontario, CA warehouse within 1 business day (Monday-Friday). Shipping and delivery times may vary. Orders placed by 12:00 pm PST Monday through Friday will be processed same business day if items are in stock. Orders placed on Saturday or Sunday will ship on Monday. Next-day and Express delivery options also available See the delivery FAQs for details on shipping methods, costs and delivery timesRETURNS

Easy and complimentary, within 14 days See conditions and procedure in our return FAQs

Fittings Information

Fittings with inserts are made to fit with .050" wall tubing. They do not fit with pipes. When you purchase flush fittings without tubing, please measure your tubing for OUTSIDE diameter and wall thickness to ensure material will fit together.

Care

Care and Maintenance Recommendations

To ensure the longevity and optimal appearance of Trade Diversified brass finish products, including unlacquered polished brass and unlacquered satin/brushed brass, we recommend the following care and maintenance recommendations:

Clear Coating: If you wish to prevent tarnishing and maintain the original finish of satin or polished brass, we strongly recommend specifying TDI Clear Coating during the manufacturing process. This protective coating acts as a barrier against oxidation and helps the brass retain its luster for an extended period.

Routine Cleaning: Regular cleaning is essential to remove dirt, grime, and environmental pollutants that can accumulate on the brass surface. Use a mild, non-abrasive metal polish in paste form or a solution of warm water and a gentle soap. Gently wipe the brass with a soft cloth or sponge, ensuring all areas are thoroughly cleaned. Avoid using harsh chemicals or abrasive materials that may damage the brass.

Tarnish Removal: If tarnishing occurs on brass finishes without clear coating, prompt action can restore the original shine. For mild tarnish, utilize a metal restoration polish specifically designed for brass. Apply the polish following the instructions, allowing it to dry before gently buffing the surface with a soft cloth or pad until the tarnish is eliminated. For Tarnish removal, we find acetone effective for removing fingerprints. For satin brass finishes, rebushing can also be effective in revitalizing the appearance.

Preventive Measures: Minimize direct exposure of brass finishes to harsh elements, excessive moisture, and extreme temperatures. Consider using protective covers or placing brass items in enclosed areas to reduce oxidation. Additionally, avoid contact with acidic substances, such as citrus juices or vinegar, as they can accelerate tarnishing.

Periodic Maintenance: Conduct regular inspections of the brass finish products to identify any signs of wear, corrosion, or damage. Address any issues promptly by following appropriate repair or maintenance procedures. If unsure, consult with professionals or refer to the manufacturer's recommendations.

By adhering to these care and maintenance recommendations, you can effectively preserve the appearance and ensure the optimal functionality of TDI brass finish products. This diligent approach will enhance their longevity, safeguard their beauty, and maintain their performance over time.

Brass Finish Disclaimer

TDI Brass Finish Products: General Information and Maintenance

Brass Finish Disclaimer

Brass, an alloy primarily comprised of copper (Cu) and zinc (Zn), is renowned for its outstanding mechanical properties and chemical stability. It exhibits remarkable fabricability, corrosion resistance, and inherent antibacterial properties, rendering it exceptionally versatile for a wide range of applications. However, brass is prone to tarnishing due to its susceptibility to oxidation. Oxidation is an electrochemical reaction that occurs when brass is exposed to atmospheric oxygen (O2), resulting in the formation of copper oxide (CuO) and zinc oxide (ZnO) compounds on the brass surface. This oxidation process causes the brass to darken and lose its luster shortly after manufacturing, regardless of storage or packaging conditions.

It's important to note that TDI does not provide an unconditional guarantee of tarnish or corrosion resistance for satin or polished brass finishes. However, as a proactive measure, we highly recommend the use of TDI Clear Coating during the manufacturing process. This clear coating serves as a protective barrier, assisting brass in retaining its original factory finish for an extended period. In cases where TDI Clear Coating is not applied to satin or polished brass finishes, tarnishing due to oxidation becomes inevitable. To restore brass to its optimal condition, meticulous care and maintenance procedures should be followed. Clear coated materials lack scratch resistance and are not advisable for handrail and footrail applications where constant touching, handling, and scratching of the tubing occur.

In order to offer a more resilient finish, we employ a powder coat process instead of lacquering. This process is known for its enhanced durability. However, please be advised that this option is available upon request and incurs an additional cost and longer lead time. Additionally, it’s important to note that special finished materials are non-returnable.